Make your own braided lines SOURCE: SICKPUP When cutting the braided line to length wrap half a dozen turns of insulating tape around the hose and cut through the tape, it helps to stop it fraying out. ALWAYS cut the line with a hacksaw, if you use cutters you will introduce two weak points in the brake line at either end of the hose and the hose will possibly rupture under heavy braking. Clamp the hose just tight enough to hold the hose so the inner isn't crushed |

| The end of the hose once cut will look like this. You can clearly see the inner PTFE hose and the outer braid. You can clean up the inside lip of the hose with a small scalpel. |

Next slip the nut end of the banjo onto the hose and then

fit the sealing ol

ive. The sealing olive works just the sam

|

| It's obvious when the olive is in place, look into the end of the olive and make sure the PTFE hose goes all the way up the olive as shown here. |

| Next we fit the banjo to the hose. The banjo has a sticky out nipple that fits inside the PTFE hose. |

| Pull the banjo nut up the hose to the banjo and tighten. when fully tightened there will only be one or two threads showing. |

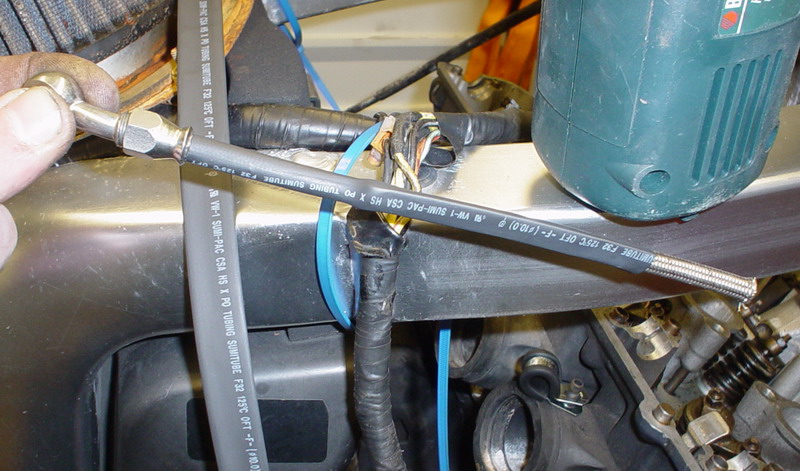

Do the same at the other end and you have your complete brake hose. Advanced Class: To protect your brake line and to stop sacrificial corrosion where the line touches fork legs or yokes the line is often covered with heat shrink tubing. To do this do as follows. Always fit heat shrink in two parts. Fit the heat shrink after fitting one of the banjo's. The first part should go from one fitted banjo to no closer than 1 inch from the other end of the hose... |

| Then add the second bit of heat shrink and add the nut for the second banjo. As you can see the banjo nut doesn't fit over the heat shrink, this is why you fit it in two parts |

| Fit the second banjo as detailed above then shrink your second piece of heat shrink and your line is finished |